Services

Maintenance Repair

One of the most significant duties performed on board a ship is marine engine repair. It entails fixing and performing standard maintenance chores on the ship’s marine engine. Repairs tend to be done by marine engine mechanics, also referred to as marine engineers.

Marine engine components must be inspected on a regular basis to prevent breakdowns or significant losses caused by a ship falling off charter. The marine engineer performs marine engine repairs based on his fundamental grasp of the equipment, sound troubleshooting expertise, and precise testing and overhauling procedures.

Onboard And Workshop Inspection / Overhauling

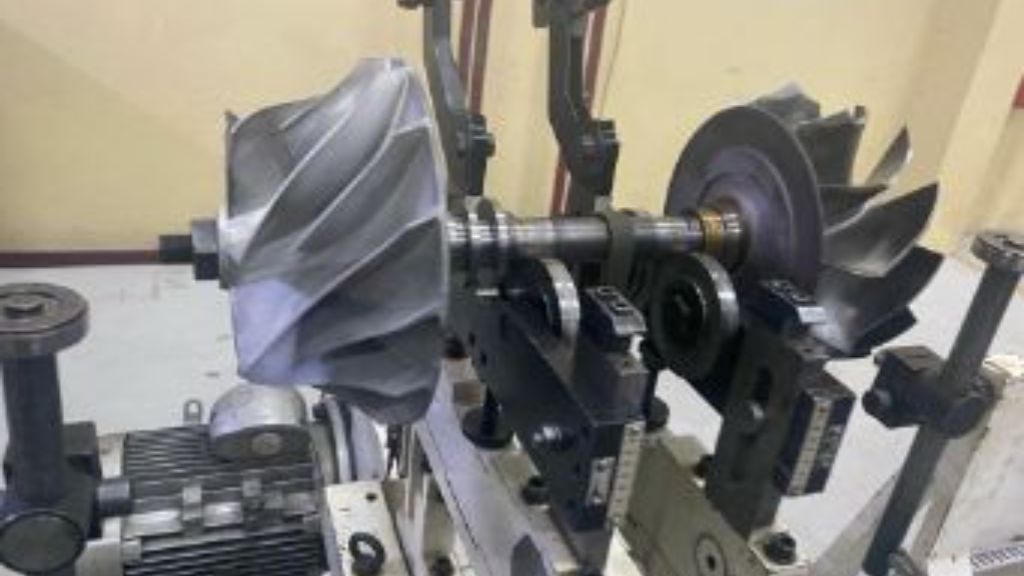

Appropriate turbocharger maintenance is vital for its effective functioning since it reduces the possibility of malfunctions, which may result in technical, operational, and financial consequences for the ship management of the company. The shipping firm and the vessel’s engine crew must pay special attention to keeping track of each turbocharger’s overhauling intervals and arranging for timely overhauling.

The following is a typical overhaul procedure:

- Analyzing every record of the technical information of the turbocharger and the engine connected to it and discussing any anomalous behaviour with the engine authorities.

- Dismantling of the required casings (air filter, air insert, gas admission), bearings, diffuser depending on the type of turbocharger, and rotor-shaft.

- Cleaning of the dismantled parts.

- Inspection of the cleaned parts according to manufacturer’s specifications (which can be visual or require a specialized method i.e., ultrasonic measurement of the thickness of the casings).

- Replacement of the required parts (after agreement with the client).

- Assembly of all the parts back to the turbocharger.

- Measurement of the clearances and checking compliance with the manufacturer’s limits.

- e casings).

- Replacement of the required parts (after agreement with the client).

- Assembly of all the parts back to the turbocharger.

- Measurement of the clearances and checking compliance with the manufacturer’s limits.

Workshop Repair

Our team is made up of skilled and knowledgeable employees who, through their attitude and devotion, thoroughly identify with the company’s accomplishments and quality objectives, consistently enhancing the level of services offered. They are continually honing their talents and broadening their knowledge by taking specialized classes and training.

Our workshop has highly efficient machines through which we can provide various services, such as:

- Dynamic balancing.

- Glass bead blasting.

- Turbine blades replace.

- Crack detection test.

- Casing leakage test.

- Welding, drilling, etc.

Balancing

Our balancing machines can balance rotors from 500g to 2000kg. All rotors proceeding out from our workshop, either as new supply units or

reconditioned components built within a full Turbocharger are balance tested & if required rectified according to manufacturer standards. Our balancing machines are calibrated and verified annually by a third-party organization to ensure accuracy in accordance with ISO standards.

Rotor Dynamic Balancing

Dynamic balancing is a method of balancing machinery that involves rapidly rotating components and monitoring the disparity using

electrical equipment. The detected imbalance may then be rectified by adding or removing weight from the spinning pieces until the impact is minimized.

We offer dynamic balancing services to customers who have rotors, fans, impellers, or shafts that need to be balanced. Our dynamic balancing machine is capable of handling weights of up to 2000 kg, achieving the highest grade of balance. We will return all products to you when the service is finished, together with a balancing certificate displaying the original and persistent readings.

Me Rotor Dynamic Balancing

Failing to balance the rotor on a regular schedule might generate vibrations which lead to significant bearing damage.

As a result of the excessive bearing wear out, the whole turbocharger might be damaged.

Turbine Blade

The turbine blade is an autonomous element that constitutes the turbine portion of a gas turbine or steam turbine. The blades are in charge of gathering energy from the combustor’s high-temperature, high-pressure gas. The turbine blades are often the most restrictive element in gas turbines.

Turbine Blade Replacement

Our specialized workforce repairs broken turbine blades with high-quality authorized materials and rebuilds them to their original configuration, according to ISO standards.